MC12020 is a typical metal rubber coating material with double side foamed nitrile rubber coating. Material overall thickness is 1.20mm. With its foamed NBR (Nitrile Butadiene Rubber) coating on SPCC (cold-rolled steel) base metal, appears to be suitable for applications that require good resistance to oil, heat, and abrasion, as well as good adhesion and mechanical strength.

| Property | Specification | |

| Rubber Type | Foamed NBR | |

| Base Metal Type | SPCC | |

| Surface Appearance | Semi-luster black | |

| Overall Thickness (mm) | 1.20±0.30 | |

| Base Matel Thickness(mm) | 0.20±0.01 | |

| Rubber Coating Thickness(mm) | 0.50±0.15 (per side) | |

| Max. Operation Temp (C) | ≤150C | |

| Rating Adhesion Test ASTM-D3359 | 100% Residual | |

| Pull Off Test (Mpa) ASTM-D4541 -09 | ≥0.8 | |

| Base Metal Hardness (HV) | 115~ 150 | |

| Unaged Physicals | Shore A duromete (Points) ASTM D-2240 | 45~55 |

| Tensile Strength Mpa (Min,) ASTM D-412 | ≥8 | |

| Ultimate Elongation (% min) ASTM D-412 | ≥200 | |

| Heat Aged (70 hrs@100C) | Change in Durometer hardness (Points) ASTM D-573 | -15~15 |

| Change in Tensi Strength ( % max.) ASTM D-573 | -30~30 | |

| Volume Change (% max.) Oil IRM 903, ASTM D-471 | ≤40 | |

| RUBBER COATINGS | |

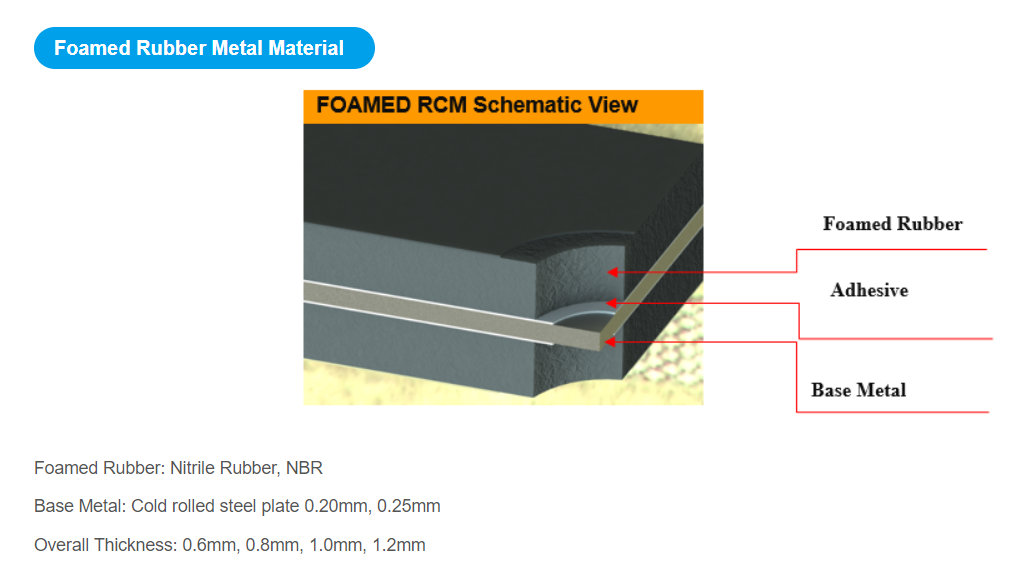

| Nitrile Butadiene Rubber (NBR) | a synthetic rubber with excellent resistance to oils, coolant, fuel, refrigerant, and other fluids. NBR offers superior abrasion resistance for metal-steel adhesion. Heat resistance up to 200↑in campe state action |

| Nitrile Butadiene Rubber (NBR) Foamet | The same characteristics of NBR, with the special benefit of higher conformance to rough sealing surfaces and lower clamp load applications. |

| METAL CORES | |

| Stainless Steel | SUS301, 3% Hard, Full Hard. SUS201 |

| Cold Rolled Steel | SPCC,1/4 Hard. C490 |

| Aluminum | |

| RELEASE SURFACE COATING | |

| PTFE | High-performance surface coating |

| Resin | Anti-stick Coating |

Excellent Shock Absorption: This material has excellent shock absorption properties, making it suitable for use in areas where vibration and impact resistance is required.

High Thermal Insulation: The foamed rubber metal material has high thermal insulation properties, making it ideal for use in high-temperature environments.

Lightweight: Despite its durability and strength, this material is lightweight, making it easy to handle and install.

Versatility: This material can be used in a wide range of applications, including automotive, aerospace, construction, and more.

High Strength: The MC12020 has high strength properties, making it capable of withstanding heavy loads and pressures.

Environmentally Friendly: The MC12020 Foamed Rubber Metal Material is environmentally friendly as it can be recycled and reused.

1. Automotive Industry: The rubber-coated metal material could be used in the automotive industry for parts that require resistance to oil and heat, such as gaskets, seals, hoses, and under-the-hood components.

2. Industrial Equipment: The material could be used in various types of industrial equipment, particularly in parts that require durability and resistance to wear and tear.

3. Electronics: The material could be used in electronic devices that require heat resistance and good electrical insulation.

4. Construction: The material could be used in construction for applications that require durability and resistance to various environmental conditions.

Please note that these are general recommendations based on the general operation conditions. The suitability of the material for a specific application should be determined through further testing and analysis. Always consult with Teamful Sealing materials engineer for advice tailored to your specific needs.