When it comes to creating a perfect seal in industrial and everyday applications, gaskets are the unsung heroes. But did you know there’s a whole science behind selecting the right gasket? Choosing the wrong one can lead to leaks, system failures, or costly repairs. So, what’s the deal with metallic and non-metallic gaskets? Let’s break it down.

What Are Gaskets?

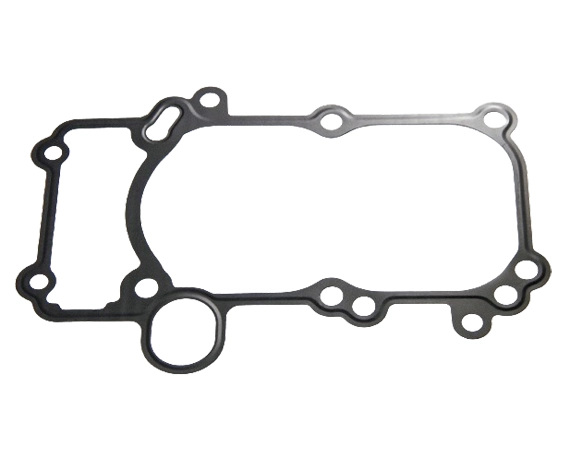

Gaskets are essential sealing components that fill gaps between two mating surfaces, preventing leaks and maintaining system integrity. Think of them as the glue that keeps everything airtight and watertight without actually being glue.

Primary Functions of Gaskets

Ensuring a Leak-Proof Seal

The main job of a gasket is to stop fluids, gases, or solids from escaping. It’s like a protective wall for your system.

Resistance to Pressure and Temperature

A good gasket can handle the heat and pressure, literally! It ensures your systems work smoothly under varying conditions.

Definition of Metallic Gaskets

Metallic gaskets are made entirely of metal or a combination of metals. They are designed for high-pressure and high-temperature applications.

Common Materials Used

Stainless Steel

Known for its strength and resistance to corrosion, stainless steel is a top choice.

Monel and Other Alloys

Special alloys like Monel offer exceptional resistance to chemicals and extreme conditions.

Key Features of Metallic Gaskets

High durability

Resistance to extreme temperatures

Perfect for industrial settings

Definition of Non-Metallic Gaskets

Non-metallic gasket materials are made from soft, pliable materials like rubber, graphite, or PTFE, making them ideal for low-pressure applications.

Common Materials Used

Rubber

Flexible and cost-effective, rubber gaskets are popular for everyday uses.

PTFE (Teflon)

Known for its non-stick properties, PTFE handles chemicals like a pro.

Graphite

Perfect for high-temperature applications, graphite is a versatile non-metallic option.

Key Features of Non-Metallic Gaskets

Flexibility and adaptability

Chemical resistance

Cost-effective for many applications

Material Composition

Metallic gaskets are rigid and durable, while non-metallic ones are soft and flexible.

Performance in High-Pressure Environments

Metallic gaskets excel in high-pressure scenarios, whereas non-metallic gaskets work better in low-pressure setups.

Temperature Resistance

Metallic gaskets can handle extreme heat, but non-metallic gaskets have limitations depending on the material.

Cost and Maintenance

Non-metallic gaskets are generally more affordable and easier to replace.

Advantages

Excellent for high-pressure systems

Resistant to extreme conditions

Limitations

Expensive and harder to install

Not suitable for low-pressure uses

Advantages

Flexible and easy to install

Cost-effective for most applications

Limitations

Limited temperature and pressure resistance

May degrade over time in harsh environments

Industrial Uses

Oil and Gas Industry

Metallic gaskets are the backbone of pipelines and refineries.

Chemical Processing Plants

They ensure leak-proof operations in chemical-heavy environments.

Everyday Uses

Plumbing Systems

Non-metallic gaskets keep your plumbing leak-free.

Food and Pharmaceutical Industries

They provide safe sealing solutions where hygiene is crucial.

Factors to Consider

Pressure and Temperature Requirements

Understand the operating conditions to pick the right type.

Compatibility with Medium

Choose a material that won’t react with the substance being sealed.

Budget Considerations

Don’t break the bank if a non-metallic option will do the job.

Importance of Consulting Experts

When in doubt, ask an expert. It’s better than a costly mistake!

Gaskets might seem small, but they’re the guardians of system integrity. Metallic gaskets shine in extreme conditions, while non-metallic ones are versatile and budget-friendly. The choice ultimately depends on your needs, but understanding the differences helps you make the right call.