When it comes to automotive engineering, there are countless components and processes that play crucial roles in ensuring a vehicle's performance and safety. One such component that often goes unnoticed but plays a vital role in the braking system is the caliper shim. In this blog, we will explore the importance of caliper shims and their role in achieving success in automotive engineering.

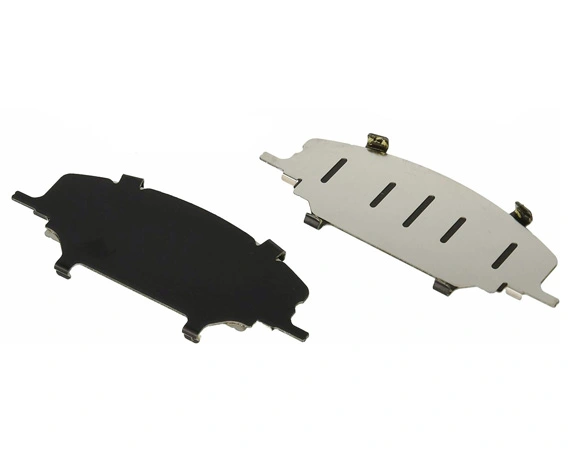

Caliper shims, also known as brake pad shims or anti-rattle clips, are thin metal or rubber pieces inserted between the brake caliper and the brake pad. These shims help to prevent noise, vibration, and harshness (NVH) that can occur during the braking process. Additionally, they provide thermal insulation and aid in reducing brake fade, improving overall braking performance.

One of the key reasons caliper shims are used in automotive engineering is to reduce noise. When a driver applies the brakes, the caliper applies pressure to the brake pads, which then press against the brake rotor to slow down or stop the vehicle. This process can often create unwanted noise and vibrations. Caliper shims effectively absorb these vibrations, reducing noise and providing a quiet and comfortable driving experience.

Another important role of caliper shims is to act as thermal insulators. During braking, immense heat is generated due to the friction between the brake pads and the rotors. Caliper shims help in dissipating this heat, preventing it from spreading to other brake components. By reducing heat transfer, caliper shims ensure optimal brake performance, preventing brake fade and maintaining consistent stopping power.

Caliper shims are also used to correct pad misalignment, ensuring even brake pad wear. If the brake pads are not properly aligned with the brake caliper, they can wear unevenly, leading to reduced stopping power and potential brake failure. Caliper shims help to align the brake pads, promoting even wear and prolonging the life of both the pads and the rotors.

In conclusion, caliper shim plays a crucial role in achieving success in automotive engineering, particularly in the braking system. These small but important components are responsible for noise reduction, vibration dampening, thermal insulation, and alignment correction. By incorporating caliper shims into automotive designs, manufacturers can enhance brake performance, improve driver comfort, and ensure the safety of passengers and pedestrians.

If you're looking for high-quality caliper shims, Teamful Sealing is the brand to consider. With years of experience in the automotive industry, Teamful Sealing offers a wide range of shims that meet the highest standards of quality and reliability. Their caliper shims are designed to withstand extreme temperatures, reduce noise and vibration, and ensure optimal braking performance.

To summarize, caliper shims may be small in size, but their impact on automotive engineering is significant. So, the next time you hit the road and enjoy a smooth, quiet braking experience, remember to thank the humble caliper shims working behind the scenes to make it all possible.