In the industrial and automotive sectors, sealing performance is one of the key factors ensuring the normal operation of equipment. Rubber-coated metal gaskets, with their superior sealing properties and wide applicability, have become the ideal choice for many applications.

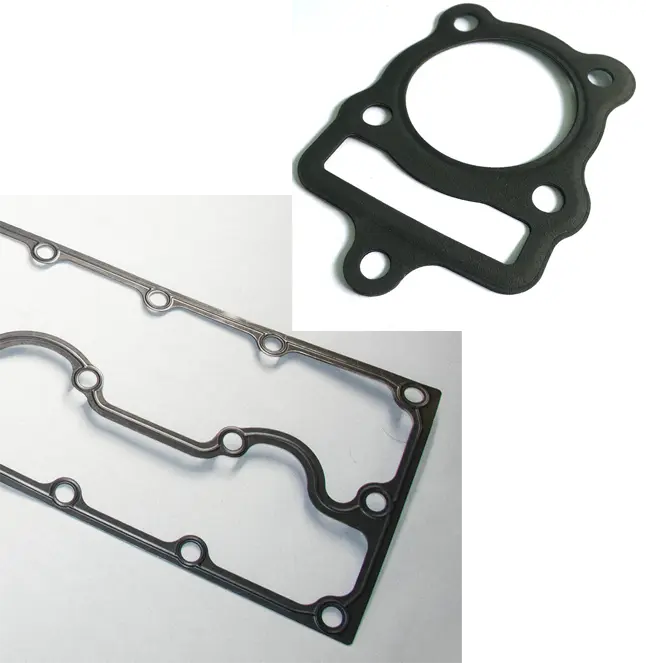

The most notable feature of rubber-coated metal gaskets is their ability to provide excellent sealing effect even under low clamping loads. These gaskets combine the rubber coating with the metal substrate, allowing them to maintain stable sealing performance even when clamping force is insufficient, minimizing the likelihood of leakage. This characteristic is particularly important for applications requiring high sealing standards, such as seals in automotive engines and industrial compressors.

To accommodate different application needs, rubber-coated metal gaskets offer a variety of rubber coating options. These options can enhance the gasket's fit to irregular flange surfaces, ensuring good sealing effect under various surface conditions. For example, in applications involving inlets and water pumps, irregular contact surfaces can affect sealing performance, and choosing an appropriate rubber coating can effectively address these challenges.

Rubber-coated metal gaskets exhibit excellent dimensional stability during prolonged use, maintaining their shape and performance through multiple tightening processes. This makes rubber-coated metal gaskets capable of sustaining good sealing performance under high load and high temperature conditions. Reliability is at the core of all sealing solutions, and these gaskets are widely used in various critical equipment due to their excellent load retention capabilities.

In automotive engines, cylinder and muffler gaskets need to withstand high-temperature and high-pressure working environments. Rubber-coated metal gaskets provide good sealing performance, reducing gas leakage and noise, ensuring smooth engine operation.

For automotive transmissions and semi-hermetic compressors, the dimensional stability and reliability of rubber-coated metal gaskets are critical. They can effectively maintain load distribution, reduce leakage, and improve the overall performance and longevity of the equipment.

In inlets and water pumps, rubber-coated metal gaskets can adapt to irregular contact surfaces, ensuring tight sealing. This plays an important role in enhancing the efficiency of fluid transmission and the reliability of the system.

Rubber-coated metal gaskets also play a significant role in oil filter adapters and oil coolers. They can withstand high temperatures and pressures while maintaining good sealing, ensuring the normal operation of the oil system.