In sealing technology, the choice of gasket is crucial for the performance and reliability of equipment. Metal rubber gasket, as a special type of sealing material, shows significant advantages in high mechanical stress and heat-resistant applications due to its excellent temperature resistance, fatigue resistance, and corrosion resistance.

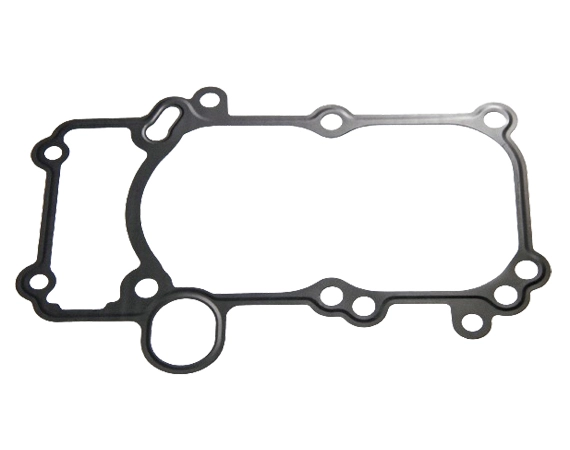

Metal rubber gaskets combine the strength of metal and the flexibility of rubber. Its core structure consists of a metal substrate and a rubber coating. This combination provides the gasket with excellent temperature resistance, fatigue resistance, and corrosion resistance. The metal substrate offers robust mechanical support and dimensional stability, while the rubber coating enhances sealing performance and adaptability, effectively dealing with various irregular surfaces and environmental conditions. This type of metal rubber gasket is particularly suitable for high mechanical stress and heat-resistant applications, maintaining good sealing performance under harsh conditions.

In contrast, traditional gaskets such as rubber gaskets, paper gaskets, or plastic gaskets generally have a simpler structure. Paper gaskets are mainly used in low-pressure, low-temperature environments. Although they are cost-effective, their heat and corrosion resistance are limited.

Metal rubber gasket performs excellently in high-temperature environments. The metal part provides outstanding heat resistance, while the rubber coating can withstand certain temperature fluctuations and maintain sealing effectiveness. Metal rubber gasket shows excellent performance in engines, high-temperature industrial equipment, and chemical fields, stably enduring high temperatures without losing its sealing properties.

Traditional rubber and plastic gaskets may soften or age in high-temperature environments, leading to seal failure. Paper gaskets have relatively low temperature resistance and can become brittle or lose functionality in high-temperature environments.

The metal substrate of metal rubber gasket grants them exceptional fatigue resistance. These gaskets can maintain stable performance under long-term mechanical stress and repeated tightening. In addition, the metal surface can undergo various anti-corrosion treatments, enhancing their corrosion resistance, especially in chemical or humid environments.

Other types of traditional gaskets generally do not match the fatigue and corrosion resistance of metal rubber gasket. Rubber gaskets may age and wear out over long-term use, while paper gaskets are prone to absorbing moisture and corroding. Although plastic gaskets have some corrosion resistance, their fatigue resistance is also limited.

Metal rubber gasket, with its unique structure and superior performance, demonstrate significant advantages in high-temperature, high mechanical stress, and corrosion-resistant applications. Compared to other traditional gaskets, it offers more stable sealing performance and longer service life, making it an ideal choice in complex and extreme conditions.